Quality Assurance

At BEPL, we focus on manufacturing quality CRGO Transformer Core Lamination to move towards energy conservation. We have set up systems that prevent the occurrence of defects and have a strict benchmark of quality standards in compliance with IS 649/3024 and all world class standards.

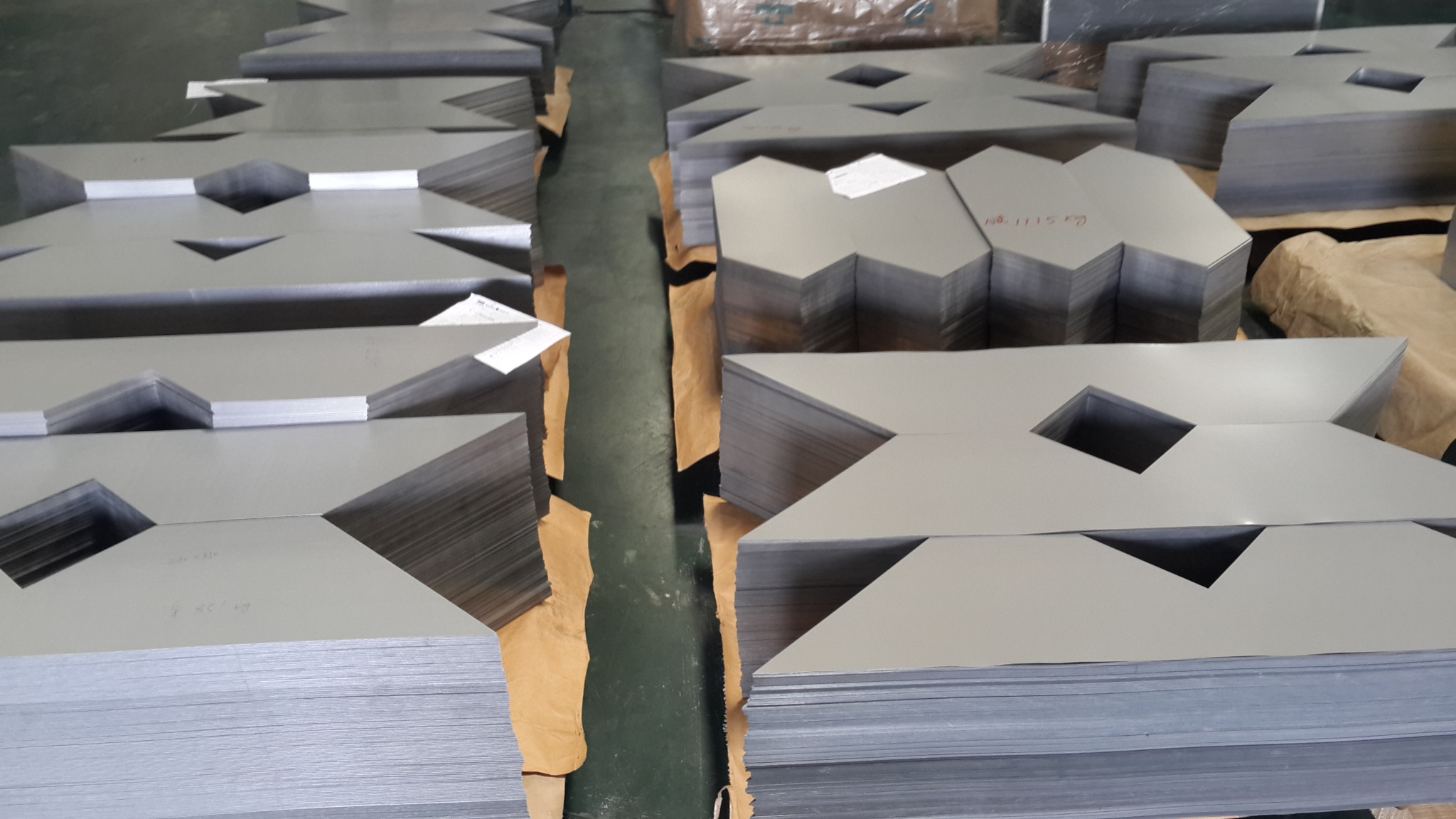

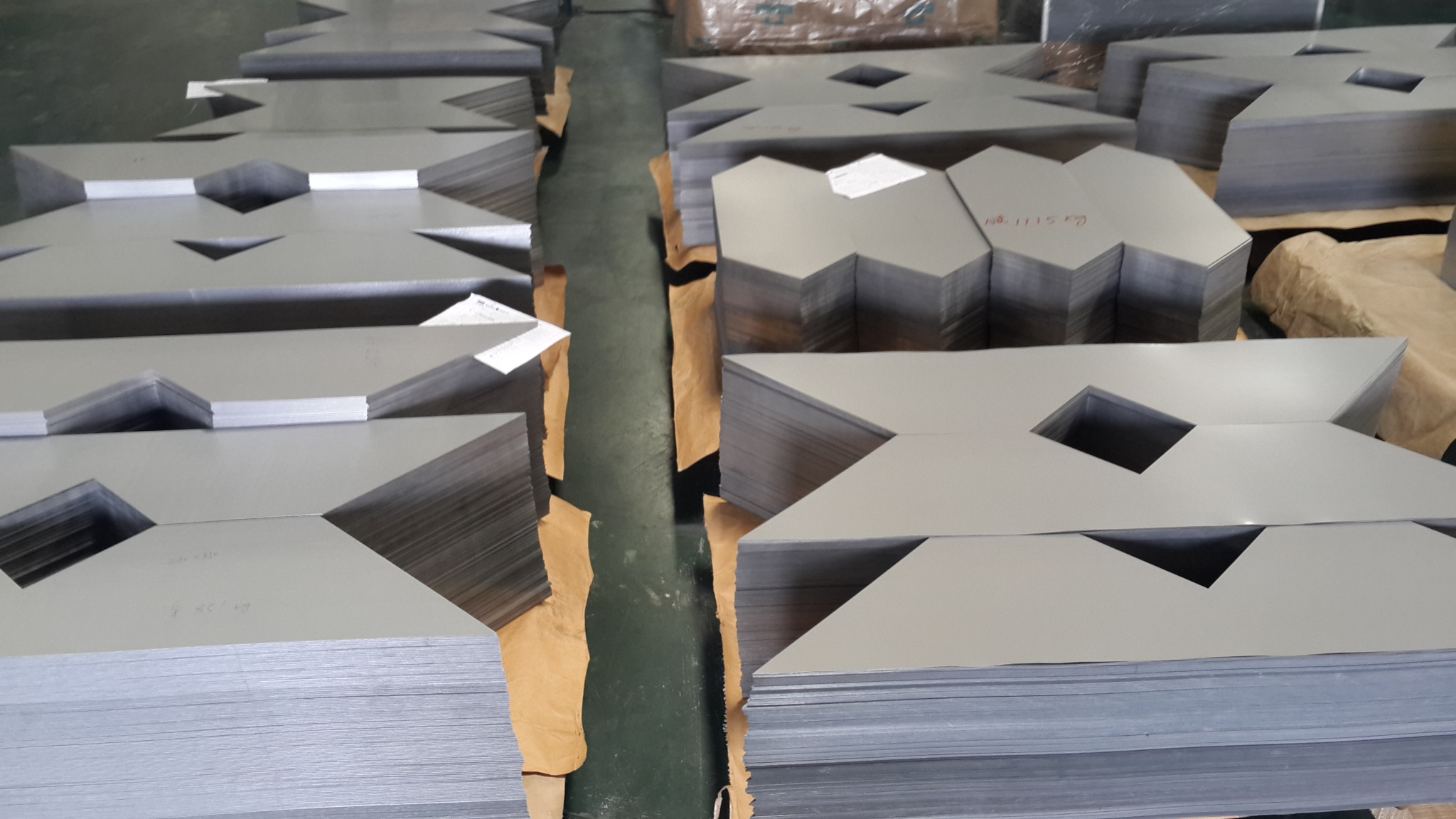

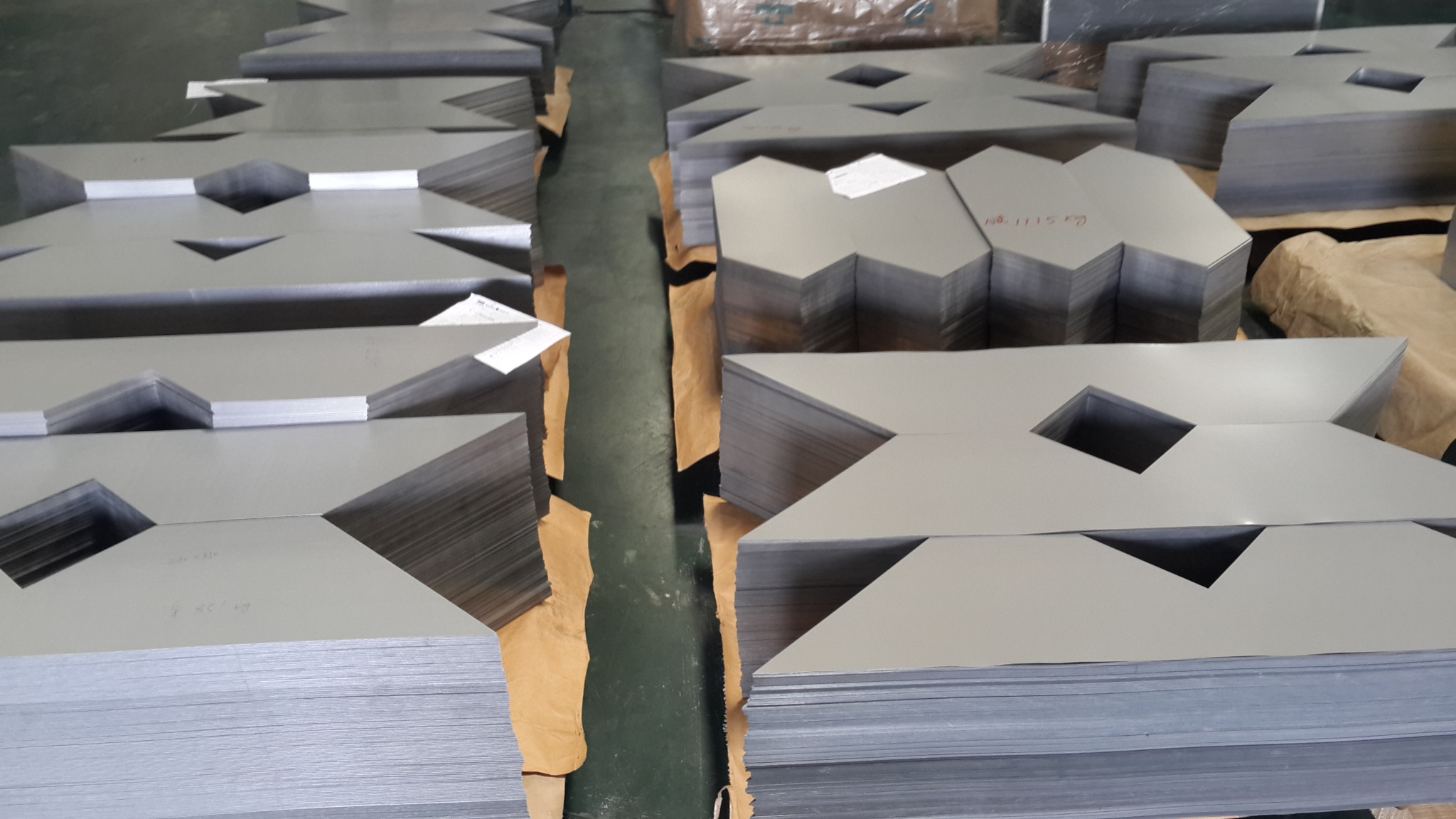

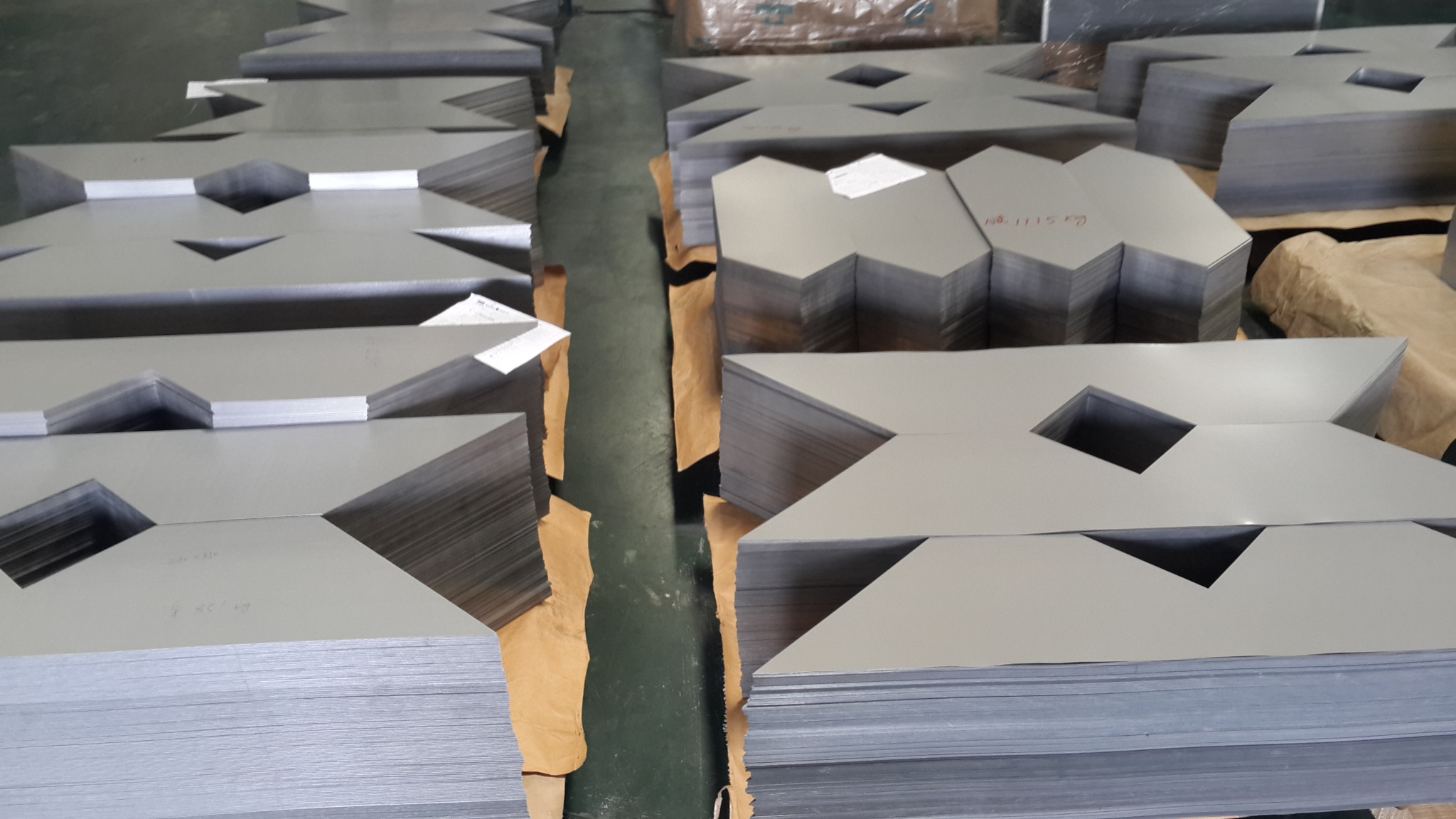

Additionally, our company is equipped with modern machinery and technology to perform quality slitting, cutting, punching, and v-notching with the most advanced automated CNC lines, test lab, and core assembly in accordance with customer requirements, supplying more than 400 MT of CRGO lamination / assembled cores per month to our reputed customers / overseas transformer manufactures

To meet our customers’ requirements, we also import CRGO electrical steel from various countries for manufacturing and supplying transformer core laminations and core assemblies.

Our Quality Policy

Banmore Electricals Pvt. Ltd. is committed to enhance CUSTOMER SATISFACTION by offering

Superior quality of transformer core lamination at a competitive price.

We aim continual improvement in our products & customer service through Quality Management System in all functional areas of the organization.

Quality Checks & Procedures

Our standard practice is to initially check the CRGO materials received/imported from the concerned miles for thickness, width, weight and no-load iron losses. During the manufacturing process, we use electronic scale, vernier callipers, micro meter, and iron-loss tester etc. to ensure that the quality, dimensions and core losses are checked and maintained at every stage.

Slitting is done with caution and ensuring the right setting of blades to diminish any burr or unwanted shear force. Tolerances in Dimensions & Shape conforms to International Standard 649/3024. Uniquely designed software is used to determine the planning of CRGO Coil slitting for optimum use of material. Cutting of material is under supervision of highly experienced personnel. Annealing of final cut core is done to remove any stress and improve iron losses using roller hearth furnace, as per customer’s requirement.

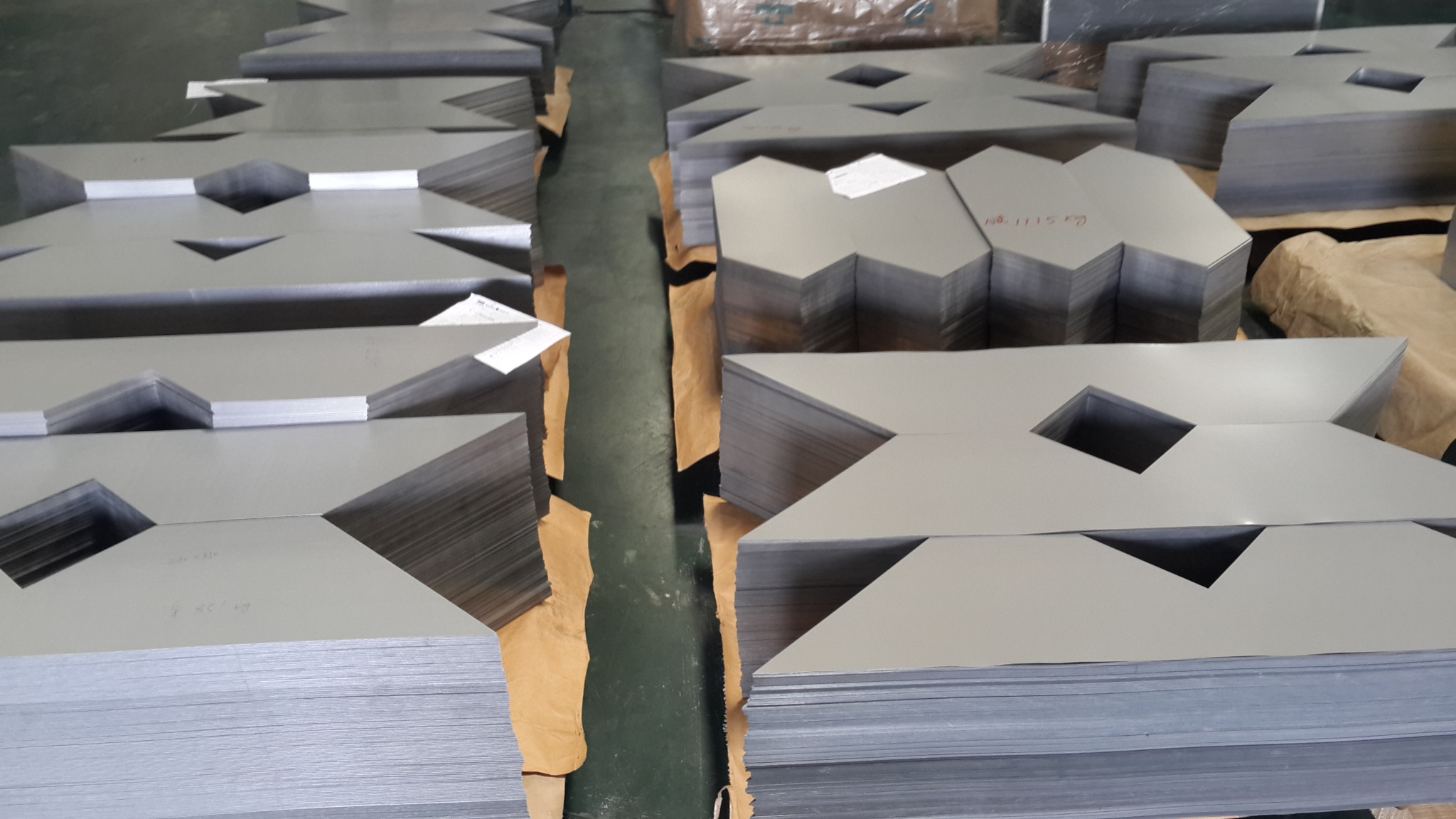

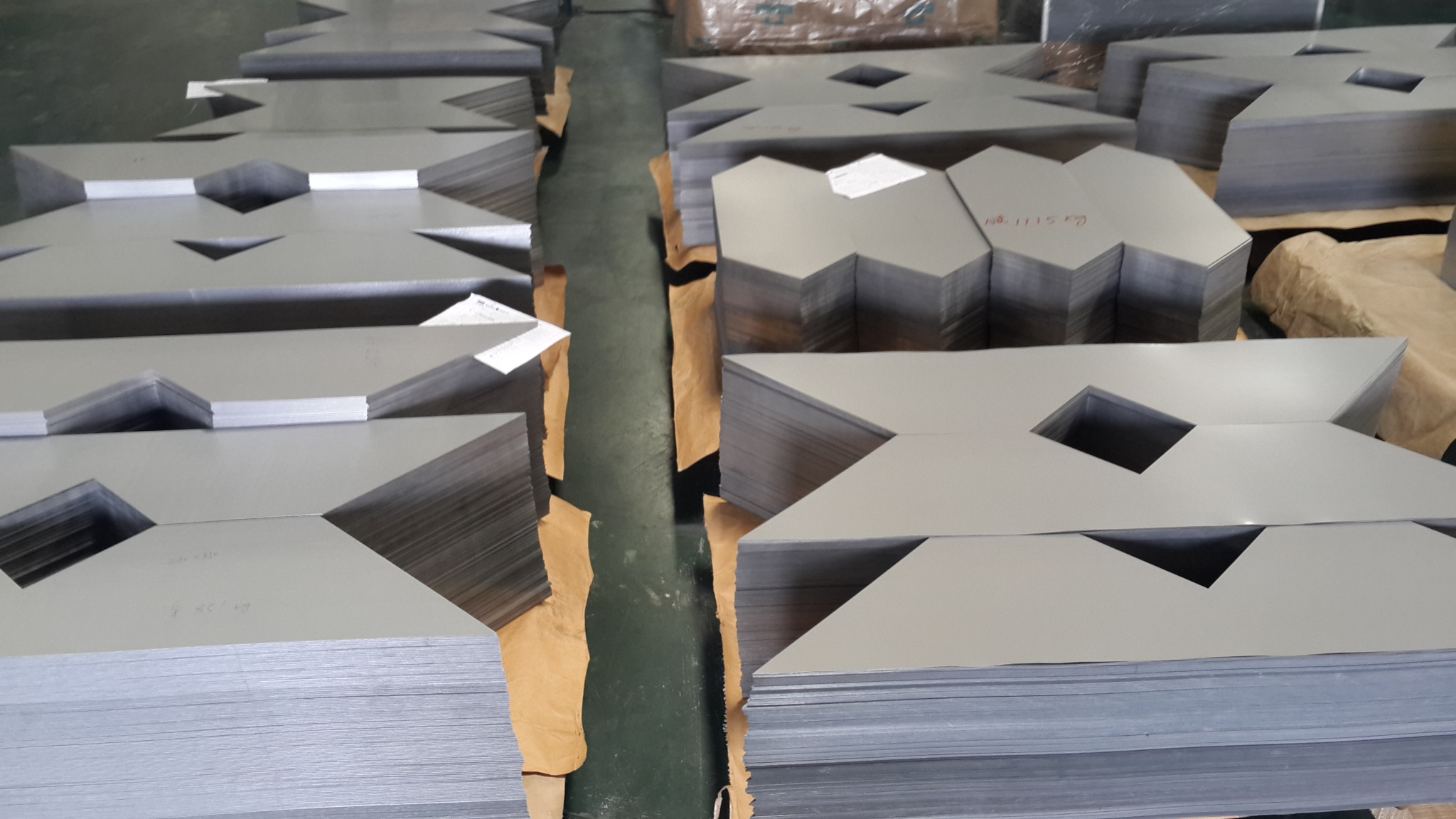

Final Lamination is checked with core-loss tester for accurate and guaranteed core losses. The finished core laminations are well packed on wooden pallets, ensuring that there is no damage to the finished product while transported.

CRGO Electrical Steel Transformer Lamination

- For power & distribution transformers up to 100 MVA.

- With guaranteed losses.

- Step-Lap cores in Completely automated CNC cut to length lines

CRGO Electrical Steel in coils/Slit coils:

- All grades of CRGO available.

- With test certificates.

- By state of the art, Automated Laser guided Slitting line with tungston carbide.

CRGO Electrical Steel Transformer Lamination

- For power & distribution transformers up to 100 MVA.

- With guaranteed losses.

- Step-Lap cores in Completely automated CNC cut to length lines

CRGO Electrical Steel in coils/Slit coils:

- All grades of CRGO available.

- With test certificates.

- By state of the art, Automated Laser guided Slitting line with tungston carbide.

Complete Assembled cores :

- As per the design required by our customers.

- With achieved losses.

CRGO Wound core/GAP CORE :

- As per the design required by our customers.

- With achieved losses.